Categories

Click

to expand category

to expand category

-

Boiler Trim Valves

- Ball Valves

- Globe Valves

- Angle Valves

- Blow Down Valves (Slow Opening)

- Blow Down Valves (Quick Opening)

- Swing Check Valves

- Lift Check Valves

- Whistle Valves

- Needle Valves

- Strainers

- Gate Valves

- Boiler Drains

- Float Valves

- Float Balls and Rod

- Tricocks

- Safety Valves

-

Water Gauge Fixtures

- Model 905 1/2" Long Shank Upper Fixture

- Model 905PW 1/2” Long Shank Upper Fixture

- Model 905A 1/2” Short Shank Upper Fixture

- Model 905APW 1/2"Short Shank Upper Fixture w/Plastic Hand Wheel

- Model 905S 1/2” Long Shank Upper Fixture with Stop Check

- Model 905SPW 1/2” Long Shank Upper Fixture with Stop Check

- Model 946 1/2” Long Shank Lower Fixture

- Model 946PW 1/2” Long Shank Lower Fixture

- Model 946A 1/2” Short Shank Lower Fixture

- Model 946APW 1/2” Short Shank Lower Fixture

- Model 946S 1/2” Long Shank Lower Fixture with Stop Check

- Model 946SPW 1/2" Long Shank Lower Fixture w/Ball Check and Plastic Hand Wheel

- Model 946AS 1/2” Short Shank Lower Fixture with Stop Check

- Model 946ASPW 1/2” Short Shank Lower Fixture with Stop Check

-

Water Gauge Fixture Sets

- Model 34011 Long Shank

- Model 34012 Short Shank

- Model 34013 1/2” Long Shank

- Model 34014 Long Shank

- Model 34015 Short Shank

- Model 34017 1/2” Long Shank Water Gauge Fixture Set

- Model 34018 1/2” Short Shank

- Model 34018PW 1/2” Short Shank

- Model 34019 Expansion Tank Fixture Set

- Model 34020 1/2” Long Shank

- Model 34021 1/2” Long Shank Less Protector Rods

- Model 34031 1/2” Short Shank

- Model 34032 1/2” Long Shank

- Model 34033 1/2” Short Shank Less Protector Rods

- Model 34036 1/2” Long Shank

- Model 34038 1/2” Short Shank

- Expansion Tank Fixtures

- Continuous Blow Down Valves

- Boiler Gauge Fixture Set

- Boiler Gauge Fixtures

- Flat Panel High Pressure Gauge Glass

- Flat Panel Gauge Glass Valve Sets

- Fire Protection Products

-

Laundry & Dry Cleaning Products

-

Valve Selector Chart

-

Head Valves

- Model 7000 Head Valve Assembly

- Model 7000C Head Valve

- Model 7000L Head Valve Assembly

- Model R121 Head Valve Assembly

- Model R121A Head Valve Assembly with Bushing

- Model R121AB Head Valve Assembly with Bushing

- Model R121AC Head Valve Assembly with Bushing

- Model R121ANY Head Valve Assembly with Bushing

- Model R121B Head Valve Assembly

- Model RA111 Head Valve Assembly with Gaskets & Guides

- Model VC21NY New Yorker Cylinder Actuator

- Model X121 Head Valve Assembly

- Model X121A Head Valve Assembly with Bushing

- Model X140 Head Valve Assembly

- Model X140A Head Valve Assembly with Bushing

- Model X141 Head Valve Assembly

- Model X141A Head Valve Assembly

- Model X141AB Head Valve Assembly

- Model X141B Head Valve Assembly

- Buck Valves (manual)

- Buck Valves (pneumatic)

- Air Vacuum Valves (manual)

- Air Vacuum Valves (pneumatic)

- Steam Vacuum Valve

- Oil Check Valves

- Air Circuit Valves

- Spotting Board Valves

- PTFE Steam Hose Assemblies

- Hoffman Model V Parts

- Hoffman Model R Parts

- Hoffman Model X Parts

-

Valve Selector Chart

-

Electrical Apparatus Valves

- Sampling Devices

- Needle Test Valve

- Globe Valves

- Angle Valves

- Ball Valves

- 125 Series Sampler Valves

- 127 Series Sampler Valves

- 127 TF Series Sampler Valves

- 127 TN Series Sampler Valves

- 128 Series Sampler Valves

- 129 Series Sampler Valves

- 175 Series Sampler Valves

- Radiator Valves

- Specialty Valves

- Flanged Gate Valves

- Flanged Globe Valves

- Industrial Valves

-

Custom Brass & Bronze Casting and Machined Capabilities

Information

Compare Items

You have no items to compare at this time.

Search

- Home /

- Keystone Foundry Division, Brass Castings

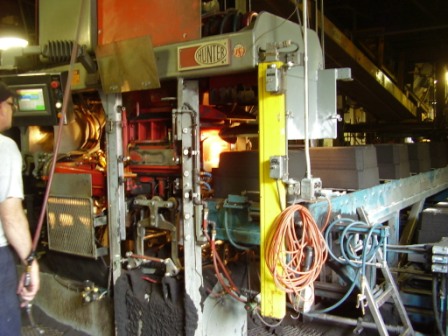

KEYSTONE FOUNDRY DIVISION

Erie, PA

Our Keystone foundry division produces high-quality, pressure tight castings in a variety of red brass alloyssuch as CDA 836, CDA 844 and CDA 922. Additional alloys poured include aluminum bronze, manganese bronze and a variety of lead-free alloys.

Keystone is an ISO 9001 registered facility. Click here to download a copy of Keystone's ISO Certificate. View our Keystone Foundry facilities list here.

To contact Keystone Foundry click here. Our design and manufacturing capabilities include pattern equipment design from customer drawings or samples plus stereo lithography and solid modeling. Our in-house pattern and tool shop enables on-site repair, maintenance or modifications to both matchplates and core boxes. We also offer complete machining capabilities, pressure testing and impregnation services.

To view a casting simulation, click on the video below.