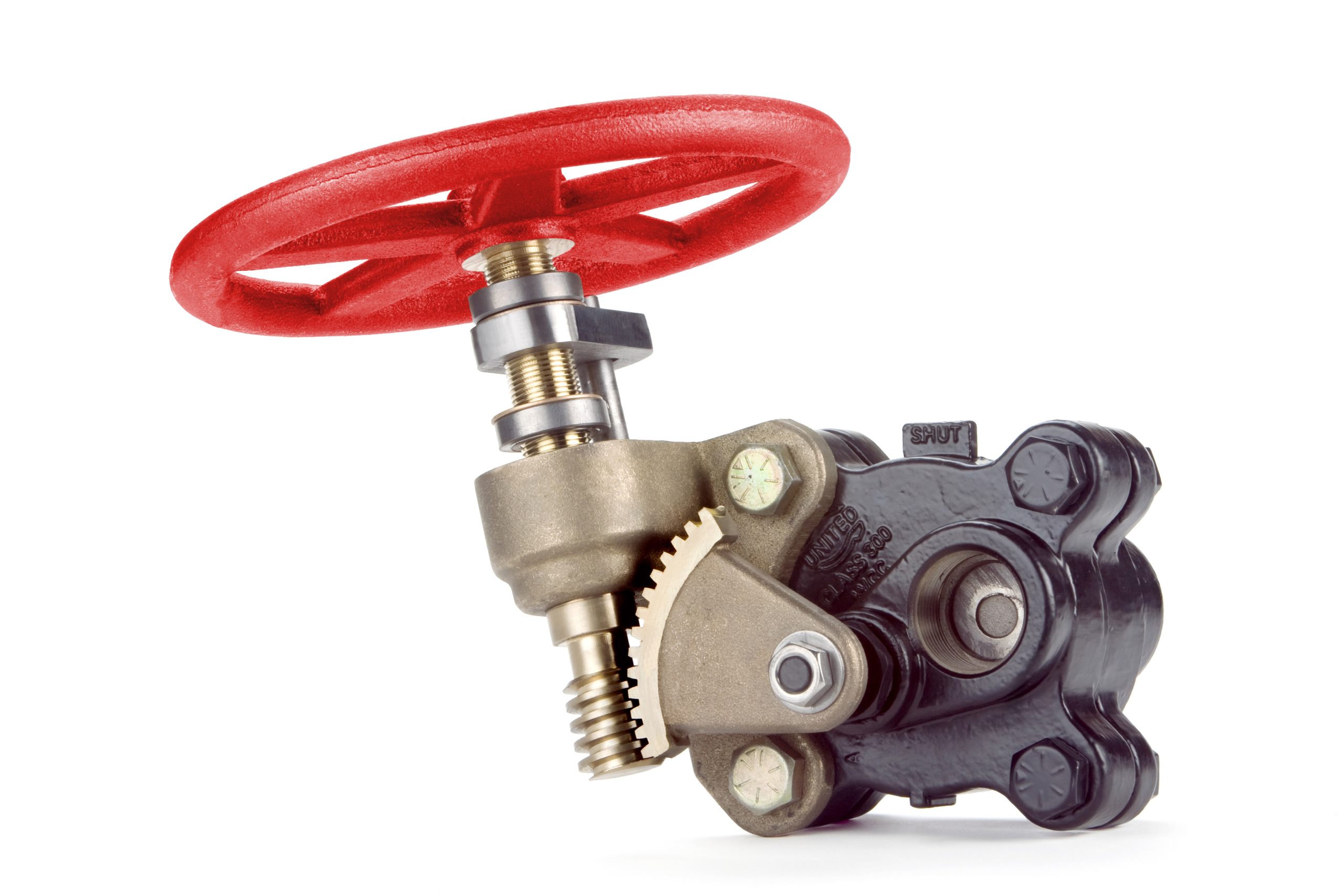

Slow-Opening Blowdown Valves

Efficient Boiler Operation with Slow-Opening Blowdown Valves

At United Brass Works, our slow-opening blowdown valves are specifically engineered to meet the rigorous demands of boiler systems in industrial and commercial applications. These valves play a crucial role in maintaining boilers’ water quality and operational efficiency by helping to remove dissolved solids and impurities that naturally accumulate during operation. Without proper blowdown processes, boilers would suffer from scale buildup, reduced efficiency, and, eventually, component failure. Our slow-opening blowdown valves ensure reliable performance and durability, even under high-pressure and high-temperature conditions.

Why Choose Slow-Opening Blowdown Valves?

Slow-opening blowdown valves allow operators precise control over the flow rate of water or steam released during the blowdown process. This gradual flow control minimizes thermal shock to the drain pipes, which can occur with sudden, high-velocity steam or water discharge. When a slow-opening valve is engaged, the operator turns the handle several times (typically three full rotations) to fully open or close the valve, allowing controlled venting that reduces wear and tear on the system components.

Key Features of United Brass Works’ Slow-Opening Blowdown Valves

Our slow-opening blowdown valves are built from high-quality materials, including bronze and carbon steel, to withstand the corrosive and erosive conditions commonly found in boiler environments. Each component—stem, disk, and seat—is designed with durability in mind:

- High-Quality Materials: Using corrosion-resistant materials like bronze and carbon steel ensures the valve’s longevity, even in a boiler’s harsh environment.

- Precision Engineering: Our valves are engineered to close tightly, preventing leaks and minimizing the chance of sediment buildup within the valve seat.

- Operator Safety: Our slow-opening blowdown valves provide safer operation by allowing gradual release, reducing the risk of accidental exposure to high-pressure steam or hot water.

- Easy Maintenance: Designed for easy in-line maintenance, our valves help minimize downtime by allowing routine checks and repairs without needing special tools.

How Slow-Opening Blowdown Valves Work

In boiler applications, the slow-opening blowdown valve is typically part of a two-valve system, often paired with a quick-opening valve. In this configuration, the quick-opening valve is opened first, then the slow-opening valve is gradually opened to allow controlled water drainage and impurities. This approach improves safety by reducing thermal shock and minimizing erosion within the piping system.

For high-pressure boilers, gradually controlling the release of water and steam to protect the boiler structure and related components is essential. Slow-opening blowdown valves perform this critical function, preventing damage that could result from sudden changes in temperature or pressure.

Applications of Slow-Opening Blowdown Valves

Slow-opening blowdown valves are versatile and suitable for a variety of applications, including:

- Industrial Boilers: Maintains water quality by removing impurities and maintaining appropriate water levels.

- HVAC Systems: Protects equipment by controlling the gradual release of water, reducing the risk of cavitation and component wear.

- Power Generation: Ensures the safety and efficiency of high-pressure steam systems in power plants.

- Petrochemical Processing: Maintains the integrity of high-temperature equipment, helping to prevent buildup and erosion.

Advantages of Slow-Opening Blowdown Valves

The benefits of slow-opening blowdown valves extend beyond simple drainage. With features designed for both efficiency and longevity, these valves offer:

- Reduced Erosion: By allowing gradual drainage, these valves reduce the impact on piping and equipment, enhancing system longevity.

- Enhanced Safety: Controlled release helps prevent accidents and enhances operator safety.

- Improved System Efficiency: Regular blowdown ensures that boilers operate efficiently by preventing sediment accumulation and scaling.

- Lower Maintenance Costs: Slow-opening valves contribute to cost savings over the boiler’s lifespan by reducing the need for frequent repairs and replacements.

Model 226UT Y-Blow-Off Valve

Model 525 Slow-Opening Blow-Off Valve

Contact Us for Slow-Opening Blowdown Valves

United Brass Works provides a wide range of slow-opening blowdown valves in various sizes and configurations to suit different boiler systems. Our team of valve specialists is here to help you find the right solution for your system.