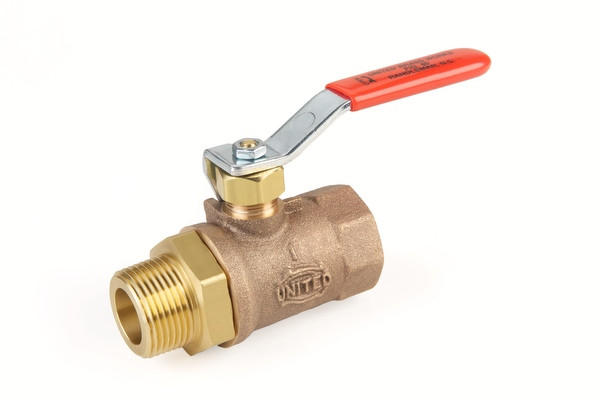

Ball Valves

Simple and Versatile

Ball valves are the most commonly used valves in our extensive line of boiler trim valves. At United Brass Works, we often recommend ball valves as a flow control device because they’re durable, reliable, and easy to use. Their simple design means they rarely need to be repaired; if they do, the repairs are easy. If made correctly and using the right materials, ball valves will continue to perform well after many cycles.

What Is a Ball Valve?

You can skip this section if you’ve worked with valves for decades. But if you’re new to this, here’s an explanation of ball valves. The “ball” in the name is a rotating sphere hollowed out with a tunnel through the middle. The ball controls the flow of a fluid (like water) or a gas. We’ll use water in our explanation. When the valve is open, the ball is turned so the tunnel, or hole, is lined up with the pipe, and the water travels through the ball’s tunnel. Using an attached handle, the ball can be turned 90°, causing the holes to no longer line up, and the valve is now closed.

Ball valves may have several ports. Two-way ball valves feature two ports for typical on/off control. Multi-port ball valves are used when the water must flow based on several commands or if there’s more than one water source. Ball valves are easier to turn on and off than other valves since they only need a 90° rotation of the ball. Ball valves can have manual or pneumatic actuators, and United Brass Works makes both.

Ball valves are mainly used for non-slurry applications but are also suitable for other applications requiring tight shut-off.

Another Good Reason to Use Ball Valves

Here’s one more excellent feature of well-made ball valves: they close securely even after long periods of not being used. This feature and the above traits make ball valves ideal for shutoff and control applications like boilers.

Ball valves are sometimes called gate or globe valves, but they differ. You have finer control with gates and globe balls, especially in throttling applications, but that doesn’t necessarily make them better than ball valves. Like all valves, the best type or model to use depends on how the valve will be used and the type of equipment it’s installed on. The valve experts at United Brass Works can tell you which model would be the best option for your project.

The Downside of Ball Valves

One drawback to ball valves is that when they’re used for controlling water – they trap some water in the center cavity of the ball while in the closed position. If the ambient temperature falls below the freezing point, this water will freeze and may cause the sides to crack. But as long as you are aware of this possibility, you can take steps to prevent it.

Ball valves also lack a precise level of control. As mentioned above, a gate or globe valve may be a better option if a finer amount of control is needed. Other than that, there are few drawbacks to a well-made ball valve. More intricate systems may require a more sophisticated valve, but for many industrial processes, a ball valve is exactly what’s needed.

Ball Valve Features

- Simple design

- Durable and reliable

- Will close securely even after long periods of disuse

- Able to support pressures up to 1,000 bar (100 MPa; 15,000 psi) and

- Functions in temperatures up to 750 °F (400 °C), depending on design and materials used.

- Sizes typically range from 0.2 to 48 in (5 to 1200 mm).

United Brass Works has ball valves ranging from ¼” to 2.” Click on the links below to see the specifications of the one you’re looking for. Let us know if you don’t see what you’re looking for.

Model 80 Ball Valve

Model 80MXF Ball Valve

Have Questions About Ball Valves?

Don’t hesitate to contact one of our valve specialists by clicking here or calling 800.334.3035. United Brass Works has been making high-quality valves and gauges for over 100 years, and we’re happy to answer any of your questions.